Yakatangwa muna2009, Alicolor anogadzira masero eSalar, uye masisitimu emasimba, anonyanya kuita zvekutsvagisa nekuvandudza, kugadzirwa uye kutengesa kwePV modules; Zviteshi zveMagetsi uye zvigadzirwa zvehurongwa etc. zvarin zvahwo zvekutakura zvePV Modules akange apfuura 80GW.

Sezvo muna 2018, Alicosolar inowedzera bhizinesi inosanganisira sosi yeprojekiti yekuvandudza Alicosolar yakabatana pamusoro pe2,5gw yeiyo solar simba zvidyarwa kune grid pasi rese.

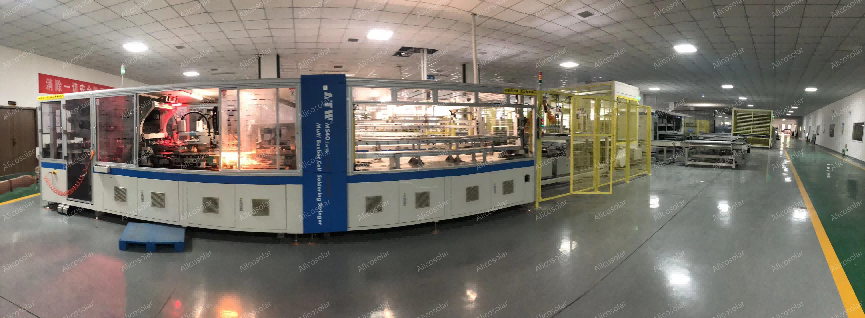

Shopu yedu yebasa

Yedu yekuchengetedza

Giredhi rese re solar sero, kusunungurwa kubva mukuongororwa

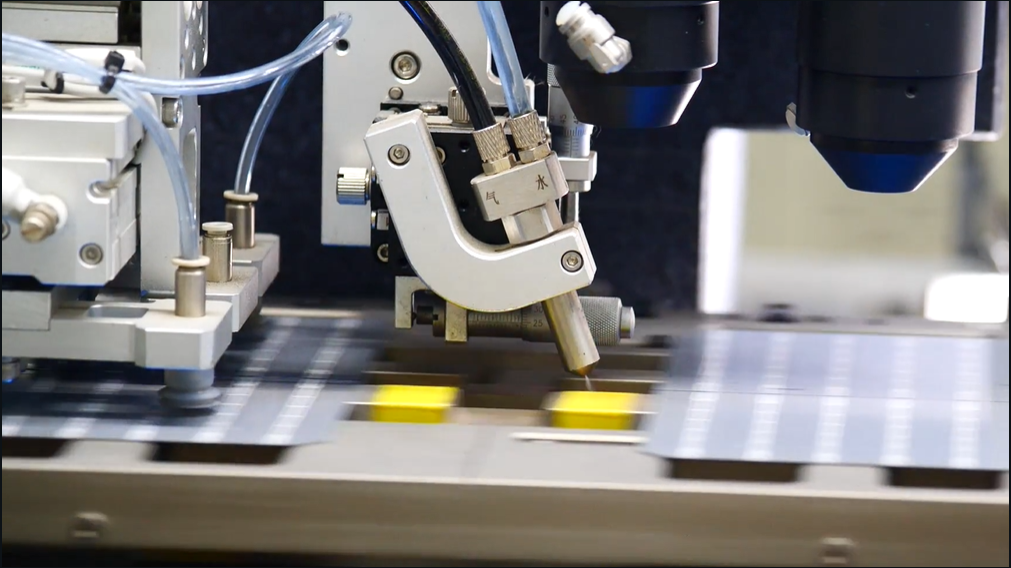

Nhanho 1-Laser Scabling, inowedzera zvakanyanya kufumura kunze kweyunivhesiti

Nhanho yechipiri-tambo tulating

Panguva ino-kuyambuka ar coating kutsamwa girazi, eva uye ipapo pile yakakwira kumirira

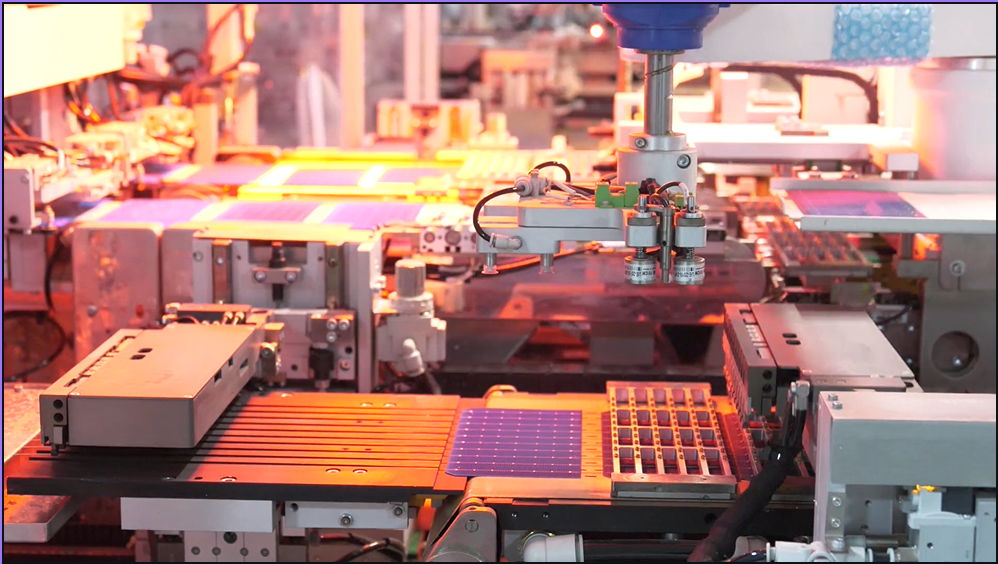

Nhanho 3-otomatiki tesetting muchina pane yekumirira girazi uye Eva

Nhanho 4-yakareruka alding uye kuomesa.

Shandisa muchina wakatemwa welting (akasiyana tolding kusimudza kwemasero ehukuru hwakasiyana) kuti afukidze mitezo yemasero anotenderera, uye ita otomatiki pamba, uye wozozvisunga tepi-tembiricha yekupisa.

Nhanho 5-iyo bhatiri tambo, girazi, Eva, uye kudzokera kumashure zvinoenderana neimwe nhanho uye kugadzirira kusvika kumusoro: girazi, bhatiri, Eva, girazi fiber, kudzokera kumashure).

Nhanho 6-chitarisiko uye El bvunzo

Kutarisa kana paine madiki madiki, kana bhatiri rakaputswa, rakarasika makona, etc.unqualfied cell richadzoka.

Nhanho 7-Laminated

Iyo yakagadzirirwa girazi / bhatiri tambo / Eva / kumashure kwepepa richayerera mumhepo, uye mhepo iri mucheki ichanyungudika nekudziya nekudziya kubatanidza bhatiri, girazi uye bepa rekuseri pamwe chete, uye pakupedzisira tora gungano racho kutonhora. Kuongororwa kwekutanga idanho rinokosha mukugadzirwa kwezvikamu, uye kusarurika uye kuedza kwekuedza kutsunga maererano nezvivakwa zveEva. Iyo nguva yekuedza kutenderera inenge iri maminitsi gumi nemashanu kusvika makumi maviri. Tembiricha yekurapa iri 135 ~ 145 ° C.

Primary process inodzora: Mhepo mabhuru, mabvumirano, makomba, mabara uye splinter

Nhanho 8-module process kuridza

Mushure mekumuka, zvikamu zvevakarembera zvinoyerera kuchembera, uye madziro emukati wemadziro emukati anozotambuka mushure mekamuri yemuchina, uye otomatiki chimiro chakarohwa uye chakamiswa pane laumator. Makona ezvikamu zviri nyore kuiswa kweinjiniya.

Main process Controls: makomba, mahombekombe, matsvina, glue inodonha pazasi, yekuisa mabhuruku uye kushomeka kwegwenzi.

Nhanho 9-Kubatana

Izvo zvikamu zvine chimiro uye bhokisi rejunction yakaiswa mumutambi wepamberi inoiswa mumutsara wekurapa kuburikidza nemuchina wekutamisa. Chinangwa chikuru ndechokuporesa iyo selant yakaiswa kana chimiro uye bhokisi remujoni rwakaiswa, kuitira kuti uwedzere kusimbisa mari uye kuchengetedza zvikamu kubva munzvimbo yakatsaurwa nehasha dzekunze. pesvedzero.

Main process Controls: Kurapa nguva, tembiricha uye humidity.

Nhanho 10-Kuchenesa

Iyo compence chimiro uye bhokisi junction bhokisi rinobuda mumutsara wekurapa rakabatikana zvizere pamwe, uye chisimbiso chave chakarapwa zvizere. Kuburikidza ne360-degree degree muchina, chinangwa chekuchenesa kumberi uye kumashure kwemativi egungano parutsetse wesangano unowanikwa. Izvo zviri nyore kurongedza mumafaira mushure mekutevera bvunzo.

Main process Control: Kuchera, kuongorora, matanga ekunze.

Nhanho 11-bvunzo

Kuyera maitiro emagetsi ekuita kuti uone zvikamu zviyero. LV bvunzo - kuyera iyo yemagetsi perform parametes kuti uone giredhi rechikamu.

Tumira nguva: Jul-28-2022